Customization may not always be top of mind when machine designers are selecting motion control vendors. The hope is usually that they will find exactly what they need in the catalog and avoid what they believe to be the higher costs, delays and risks associated with custom solutions. But, given that more than 25 percent of motion system projects end up requiring at least some degree of customization, it could be beneficial to prepare for that eventuality from the outset.

Including customization expertise on your list of vendor selection criteria could help avoid higher costs and delays if your application should require some modification down the road. And, as you learn about the varying customization capabilities of different vendors, you might just find that customization can be much faster, less expensive and not as risky as you may have thought.

The most important question to ask before closing on any motion control purchase is “What happens if we can’t get my needs met with standard products?” A few key factors to consider include:

1. Commitment. For some vendors, customization is part of their business model, while for others, it is something to be avoided at all costs. If the vendor website has dedicated customization pages with detailed lists of characteristics that can be customized, you are probably in good hands. If, on the other hand, there is little or no mention of customization, you should find out why. It could be because of deficiencies in any of the other areas mentioned below on this list.

2. Experience. How often have they had to modify a product? Can they give examples? How did the need for customization impact cost and delivery?

3. Capability and scale. Do they have any special equipment for customization? What does it do? What is the minimum number of potential products for which they would consider customization? Are they set up to handle smaller batch runs or will they customize only for large product runs?

4. Supply chain flexibility. Are they vertically integrated so that they build most of their subcomponents from raw material, or will they be waiting for your parts to arrive on the next container boat?

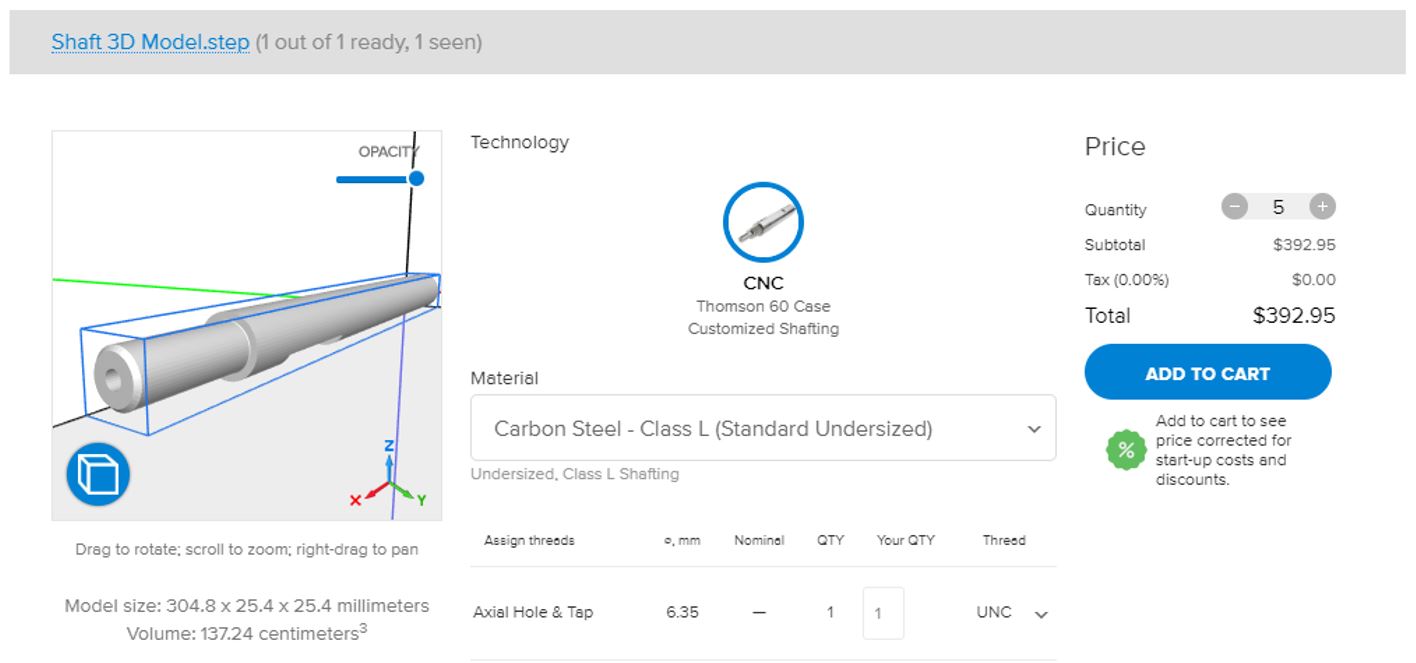

5. Process. Can they give budgetary quotes right away? How long does it typically take to get a quote for a nonstandard product? Will there be a dedicated engineer? Can you build the prototype online? Can the vendor produce the product directly from a CAD model?

Online resources such as the Instant 3D Quote Tool from Thomson Industries (pictured) allow designers to upload a CAD file, make real-time changes, choose a material, and receive a quote and lead time immediately, thereby saving them costly time and keeping projects on track.

6. Engineering problem-solving. After all else is considered, perhaps the most important factor is the creativity of the vendor’s engineering team in terms of helping you reach an optimal solution. Will they take the time to understand your needs?

While it is common for machine builders to think of customization as an all-or-none situation, many needs can be met with a relatively simple modification of standard products, which, depending on the vendor’s experience, can often be delivered in days rather than weeks or months. Sometimes all that is needed are some special machined shafts, connectors or mounting ends. Here are some examples of linear motion customizations that have helped designers adapt to irregular spaces, improve ergonomics or reduce costs.

Adapting to irregular spaces

Usually, the need for customization often emerges after the project begins. For example, a company that itself specializes in customizing semi-trailers required several modifications to adapt actuators for use in ramps, stairs and movable floor assemblies. Fitting ramp lift actuators inside the trailer wall required rotating the motor 90 degrees. The ability to mount actuators within custom ramp frames while still connecting to the standard mounting points required extending the actuator tube by four inches. Simplifying future maintenance involved retrofitting the wiring connections with an easily detacheable harness.

Lowering the price point

Even if the business relationship begins with a customization need, it can sometimes be met inexpensively by mixing and matching standard components. For example, a supplier of CNC tubing and pipe bending systems sought help in designing a new machine to meet market demand for a scaled-down system. Their high-end system used two linear slides bolted together in a cross configuration to control motion on an XZ axis, using stepper motors to drive a 2-foot ball screw on each axis. The long length of the screw required support bearings on both ends and a special coupling to the stepper.

The first thing the linear motion component manufacturer did to reduce the cost was shorten the shaft to an 11-inch lead screw with a 6-inch drive, which eliminated the need for support at both ends. Specifying a stepper motor with an integrated motorized lead screw (MLS), reduced the need for external support further because the MLS motor bearings could support the load themselves. And because the lead screw and MLS rotor are combined into one part, there was no longer a need for external coupling of the screw and the rotor.

An open palette

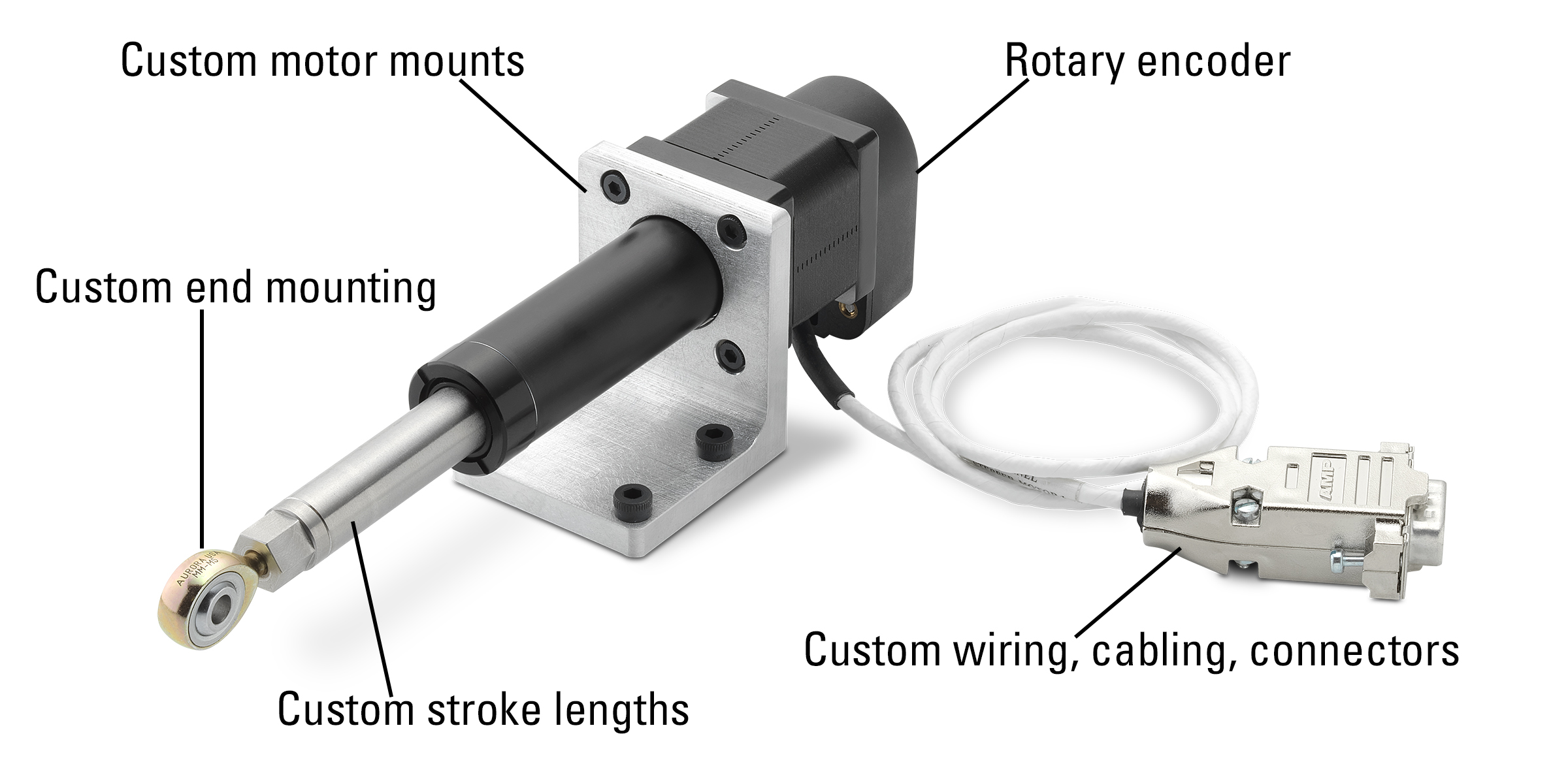

These are but a few examples of customizations. The range of options is wide. You might customize stroke and extracted length down to millimeter scale; enhance control by adding encoders; comply with industry regulations be adding certification; select a more aesthetically pleasing finish; implement a custom adapter housing; or improve voltages or clutch handling. Even those are just mere examples of what could be customized on an electric actuator. This same degree of customization applies to shafting, screws, Ball Bushings®, linear guides and a host of other linear motion components.

Collaborating with a manufacturer that has vast experience in customizing linear motion components produces both immediate benefits for the design project as well as long-term benefits for the application. The several modifications called out for this Thomson motorized lead screw actuator illustrate potential examples of how the overall design process can be simplified, and designers can save time and costs in specifying additional parts.

In these days, in which machine designers are having to do more, faster and with fewer people, the more uncertainty they can drive out of the process, the greater their chance of sustained success. Acknowledging the fact that the need to customize some aspect of your project is a likely possibility and taking a few minutes to be comfortable that you have partnered with a vendor that has deep customization capability can save you money and headaches down the road.

Sidebar

Busting myths about linear motion product customization

| MYTH | REALITY |

| Customization requires extensive end-to-end testing | Most customization involves simple modifications to standard products that have already been fully tested. |

| Slow delivery | With modern prototyping and tools, CAD drawings can be fed directly into production systems. Vendors can often deliver solutions within days. |

| High cost | While costs for systems that must be purpose designed from the ground up will be higher, most routine customizations add little or no incremental cost to the initial quote. |

| Violation of loyalty to existing suppliers | Selecting vendors in anticipation of potential customization needs avoids supplier relationship problems that may arise if your chosen supplier can’t meet modification requirements that emerge later in the project lifecycle. |